Application of gold wire ball welding process in optical Module processing

Time: 2023-10-09

I. Introduction to gold wire ball welding

Gold wire ball welding, also known as gold wire bonding, as a semiconductor internal lead interconnect the mainstream process, widely used in integrated circuits in the chip package and active optical devices in the chip and the external pin interconnect.

The principle of the common gold wire ball welding equipment on the market is: gold wire in the equipment instantaneous high-voltage discharge, the end of the formation of a small gold ball (also known as FAB, Free Air Ball), the use of ultrasonic frequency of mechanical vibration, so that the ball of gold and the surface of the welded material in contact with plastic deformation, in the ultrasound complementary to the temperature and pressure conditions, so that the metal surface of the atomic layer of the outer layer of the electrons combined with each other to form the joints.

Common internal factors affecting the effect of gold ball welding are mainly four: ultrasonic output power, temperature, pressure and welding time, but also by some external factors, such as the specifications of the gold wire, weld joint material, weld joint surface cleanliness, alignment shape.

Optical device processing commonly used 25um gold wire for device internal pin interconnect, mainly based on the good ductility of gold as a metal (can be pulled into a thin enough wire and ensure sufficient tension), electrical conductivity, weldability , in order to meet the communication semiconductor fine processing requirements and high-quality electrical signal transmission requirements.

II. gold wire ball welding in the production of optical modules applications

Gold wire ball welding in the production of optical modules in the two most common applications, one of which is applied to the TO-CAN processing, the other is the COB processing technology.

2.1 TO-CAN processing

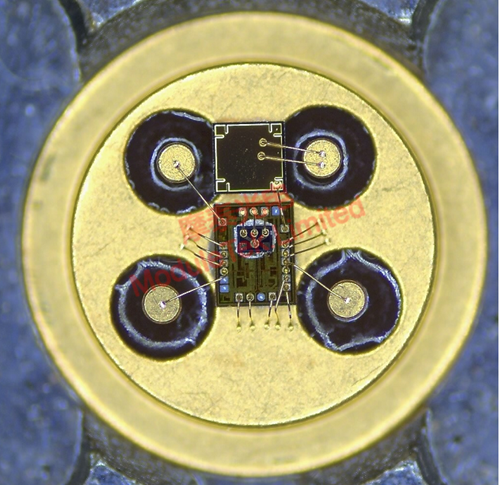

Optical devices in the TO-CAN process refers to the bare chip (Die) through the epoxy adhesive or gold-tin solder and other materials cured in the TO metal base (general base are used on the surface of the gold-plated deforestation alloy materials), through the gold ball welding the internal pins and TO pins connected to each other to form the target circuit, and then through the hermetic encapsulation of the DIE and the lead to protect the way.

Figure 1 Schematic diagram of TO-CAN internal gold wire ball soldering

2.2 COB Processing

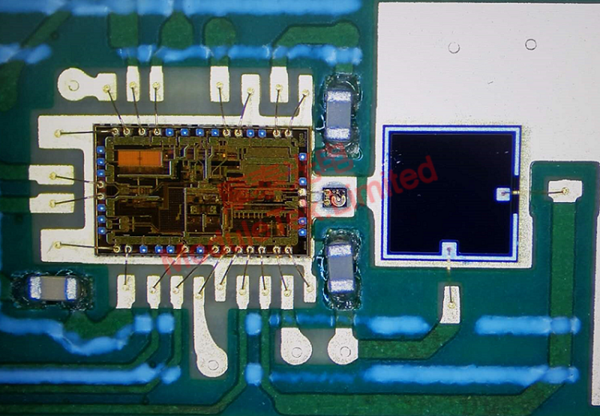

COB (Chip-on-Board) process, refers to the bare chip (Die) directly fixed on the printed circuit board, and then through the gold wire bonding, and then the chip and the lead for encapsulation and protection of the process, the signal integrity has better advantages, and has gradually become one of the mainstream process of high-speed optical module packaging.

COB process in the gold wire ball welding quality in addition to its own parameter setting factors, the circuit board surface treatment process is also an important factor affecting the effect of gold wire welding, the current market COB circuit boards respected surface process is nickel-palladium gold process. COB process details can be viewed: optical module COB process introduction.

Figure 2 Schematic diagram of COB gold wire ball welding in optical module

Moduletek Limited can provide the use of gold wire ball welding process production and processing of optical modules, welcome to buy !

If you have any questions about the above content, you can contact us by Email : web@moduletek.com

40G/100G Optical Transceivers

40G/100G Optical Transceivers 10G/25G Optical Transceivers

10G/25G Optical Transceivers 155M/622M/2.5G Optical Transceivers

155M/622M/2.5G Optical Transceivers 100M/1G Optical Transceivers

100M/1G Optical Transceivers FC 16G/32G Optical Transceivers

FC 16G/32G Optical Transceivers CWDM/DWDM Optical Transceivers

CWDM/DWDM Optical Transceivers 100M/1G/10G Coppers

100M/1G/10G Coppers Active Cable AOC

Active Cable AOC Direct Attach Cable DAC

Direct Attach Cable DAC Regular/MTP-MPO Fiber Patch Cords

Regular/MTP-MPO Fiber Patch Cords MT2011

MT2011 MT2010

MT2010 CodingBox

CodingBox