Why fiber optic connectors fail

Time: 2020-02-23

Fiber optic connectors are suitable for high speed fiber optic links, high loss fiber optic connectors may lead to network failure, which is something we don't want to encounter, fiber optic patch cord end face quality and performance problems may lead to network failure, and it is usually very difficult to carry out troubleshooting. Let's learn more about fiber optic connector failures.

1. What are the fiber optic connector failures ?

Fiber optic connector failures, may be related to the core, such as rupture inside the core, notch, slight bends, pinched, micro-fracture, etc., in addition to these are also related to the optical fiber, such as epoxy resin adhesive too much not enough or the presence of air bubbles and other unreasonable assembly process, as well as stripping, curling, and other reasons.

2.Three major causes of fiber optic connector failure

Category I issues : Dirty end face

Your problem :

Problem 1 Light propagates poorly or not at all

Problem 2 Light is reflected back to the connection point and back to the transmission point, resulting in equipment failure

Figure 1 Dust

Figure 2 Oil stains

Figure 3 Fiber

Cause When there are contaminants on the fiber endface, light may not be able to pass through the fiber endface, resulting in poor fiber loss performance.

Treatment The endface can be repeatedly inspected and cleaned to ensure that it is clean before pairing.

Figure 4 Clean endface

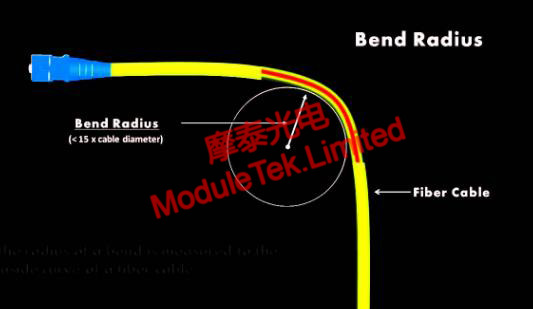

Category II issues : Exceeding the bend radius

Your problem :

Problem 1 Exceeding the bending radius, which leads to high loss;

Problem 2 Serious loss across the link

Cause Excessive bending of fiber optic cables leads to fiber loss, which we call macrobend loss, and usually occurs during installation;

Figure 5 Bending radius of fiber optic cable

Treatment Reasonable bending according to the supplier's fiber optic cable bending tolerance specification, if your installation environment of fiber optic cable bending more than the minimum bending radius, it is recommended that you can use the bend-insensitive optical fiber, usually the minimum bending radius of bend-insensitive optical fiber is 10mm.

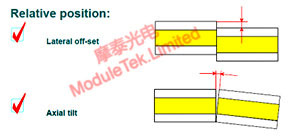

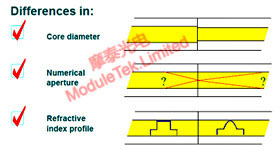

Category III issues : Misalignment

Problem 1 High loss

Problem 2 Serious loss affecting the entire link

Cause Excessive insertion loss is usually caused by fiber misalignment and different fiber materials, with both extrinsic and intrinsic factors

Figure 6 Extrinsic cause caused by poor core alignment

Figure 7 Intrinsic cause fiber material mismatch

Treatment Purchase quality components from a reliable component manufacturer.

Moduletek Limited can provide high quality fiber optic connector products, welcome to buy.

If you have any questions about the above content, you can contact us by Email : web@moduletek.com

40G/100G Optical Transceivers

40G/100G Optical Transceivers 10G/25G Optical Transceivers

10G/25G Optical Transceivers 155M/622M/2.5G Optical Transceivers

155M/622M/2.5G Optical Transceivers 100M/1G Optical Transceivers

100M/1G Optical Transceivers FC 16G/32G Optical Transceivers

FC 16G/32G Optical Transceivers CWDM/DWDM Optical Transceivers

CWDM/DWDM Optical Transceivers 100M/1G/10G Coppers

100M/1G/10G Coppers Active Cable AOC

Active Cable AOC Direct Attach Cable DAC

Direct Attach Cable DAC Regular/MTP-MPO Fiber Patch Cords

Regular/MTP-MPO Fiber Patch Cords MT2011

MT2011 MT2010

MT2010 CodingBox

CodingBox